What is intergranular corrosion in metal material?

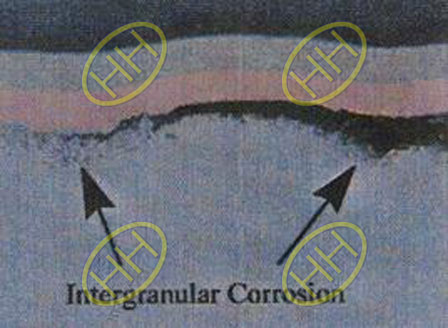

When the stainless steel pipe fittings or forged steel flange products are manufactured in our factory,we should keep attention to the intergranular corrosion of such piping products.The microstructure of metals and alloys are made up of grains,and they are separated by grain boundaries. Intergranular corrosion is localized attack along the grain boundaries,attacking the surface of the metal or alloy,it is also called intergranular attack.

The intergranular corrosion is happened a lot in stainless steel material.It’s as a result of chromium depletion,mainly come from the precipitation of chromium carbides in the grain boundaries.

When the stainless steel is under heat treatment or welding in a high temperature,Chromium carbides can be precipitated if the stainless steel material is sensitized in the temperature range 560–850°C.If the temperature lies in the critical range for too long time,chromium carbides will start to form in the grain boundaries.After that, the boundaries become susceptible to intergranular corrosion.(flange products raw material)

The area adjacent to the grain boundaries becomes depleted in chromium (the chromium reacts with carbon and forms carbides) and this zone,therefore,becomes less resistant to intergranular corrosion.

(SGS carried out Intergranular Corrosion Test to stainless steel elbows of Haihao Factory)