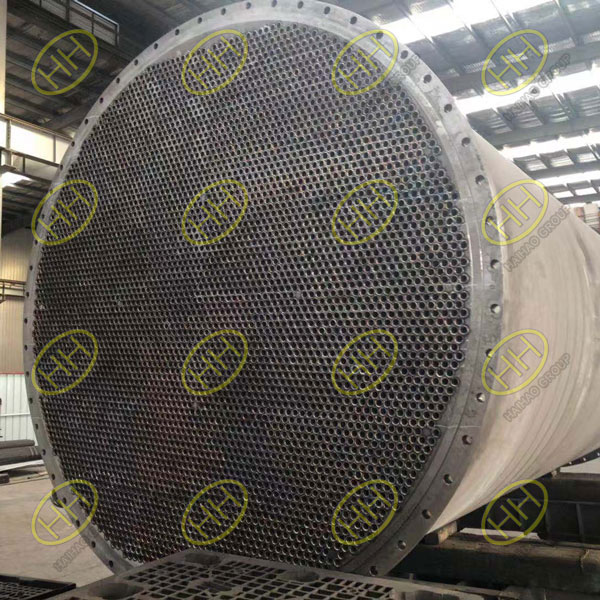

Welding and expansion method for connecting heat exchanger tube sheets and tubes

When temperature and pressure are high, and under the effects of thermal deformation, thermal shock, thermal corrosion, and fluid pressure, the connection between heat exchanger tubes and tube sheets is prone to damage. In such cases, using expansion or welding alone may not meet the strength and sealing requirements. Therefore, the commonly used method is a combination of expansion and welding.(Welding connection between heat exchanger tube sheets and tubes)

Welding for connecting heat exchanger tube sheets and tubes

The expansion and welding structure effectively dampens tube bundle vibrations, reducing damage to the weld seams, and minimizes stress and gap corrosion. This combination improves the fatigue resistance of the joints, enhancing the heat exchanger’s service life. It provides greater strength and sealing performance than using expansion or welding alone. The expansion and welding process can be divided into two types based on the sequence: expansion before welding and welding before expansion.

Heat exchanger tubesheet

Expansion Before Welding: During the expansion process, the lubricating oil used can penetrate into the joint gaps, increasing the sensitivity to welding defects like cracks and pores. These contaminants are challenging to remove entirely, making defects more likely. Therefore, when using this method, mechanical expansion is not recommended. Instead, contact expansion, while not pressure-resistant, can eliminate gaps between the tube and the tube sheet, effectively damping vibrations from the tube bundle at the weld area.

Welding Before Expansion: The primary issue with this process is controlling the precision and fit of the tube and tube sheet holes. When the gap between the tube and the tube sheet hole is small enough, the expansion process will not compromise the weld joint quality. However, the welded joint has relatively poor shear strength, so if the process is not well-controlled, it may result in over-expansion failure or cause damage to the welded joint during expansion.

Related articles:

Introduction to traditional expansion joint techniques for heat exchanger tubes and tube sheets

Introduction to new expansion techniques for heat exchanger tubes and tube sheets