Types of flange sealing surface-FF,RF,RTG,TG

Flange connections are rarely damaged due to insufficient strength,but often leak due to poor sealing.Therefore,the sealing problem has become the main problem in flange connection,and the sealing surface and gasket of flange directly affect the sealing of flange,so it is necessary to introduce them.

Flange surface needs to be processed more precisely to ensure sufficient accuracy and smoothness in order to achieve the desired sealing effect.The commonly used flange sealing surfaces are raised face(RF),flat face(FF),tongue and groove(TG),ring type joint(RTJ),SRF and male and female(MFM).

Flat Face flange:

The flat face flange has a gasket surface in the same plane as the bolting circle face.However,the contact area between the sealing surface and gasket is large (especially the wide flange used in pipeline),and the pressure required is large,so the gasket should not be positioned during installation and usually used in low-pressure, non-toxic medium containers.

Raised face flange:

The sealing surface of the flange is composed of a concave surface and a raised surface,the height of the raised surface is slightly greater than the depth of the concave surface.When installed,the gasket is placed on the concave surface, so it is easy to correct,and the bolt will not be extruded when tightened. Its sealing performance is better than plane type, but it is difficult to process.It is generally used in medium pressure vessels.

The raised face flange is the most common type used in process plant applications,and is easily to identify.It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face.This face type allows the use of a wide combination of gasket designs, including flat ring sheet types and metallic composites such as spiral wound and double jacketed types.The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint.

Ring type joint flanges:

The Ring Type Joint flanges are typically used in high pressure (Class 600 and higher rating) and/or high temperature services above 800°F (427°C).They have grooves cut into their faces which steel ring gaskets.The flanges seal when tightened bolts compress the gasket between the flanges into the grooves,deforming (or Coining) the gasket to make intimate contact inside the grooves,creating a metal to metal seal.

An RTJ flange may have a raised face with a ring groove machined into it.This raised face does not serve as any part of the sealing means.For RTJ flanges that seal with ring gaskets,the raised faces of the connected and tightened flanges may contact each other.In this case the compressed gasket will not bear additional load beyond the bolt tension,vibration and movement cannot further crush the gasket and lessen the connecting tension.

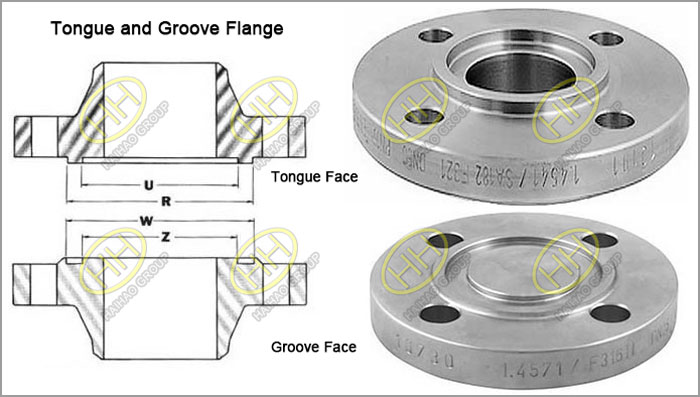

Tongue and groove face flange:

The sealing surface of the flange is composed of a tongue groove surface and a groove surface.The gasket is placed in the groove like a RF flange.The tongue groove flange will not be extruded in the groove,the compaction area is the smallest,and the gasket is uniformly loaded. Because gaskets do not contact with the medium directly,the medium corrosion effect and the penetration effect of pressure mechanism are the smallest,which can be used in high pressure,flammable,explosive,toxic media and other sealing requirements of strict occasions.This kind of gasket has good alignment in installation,and it is difficult to process and replace the gasket.

Haihao Group manufacture flanges products more than 30 years,we could produce flange surface according to clients requirement.If you have any questions,please email us:sales@haihaogroup.com