Preheating treatment of flange

The heat treatment of pipe fittings and flanges is more and more widely used in industry. The function of heat treatment is to improve the mechanical properties of materials, eliminate residual stress and improve metal cutting processability. According to different purposes of heat treatment, heat treatment process can be divided into two categories: preliminary heat treatment and final heat treatment.

The purpose of preliminary heat treatment is to improve the processing performance, eliminate the internal stress and finally prepare the metallographic structure for heat treatment. The heat treatment processes include annealing and normalizing, aging, quenching and tempering, etc.

Annealing and normalizing are used for hot worked blanks. In order to reduce the hardness of carbon steel and alloy steel with more than 0.5% carbon, annealing treatment is often used; in order to avoid tool sticking when cutting, normalizing treatment is used for carbon steel and alloy steel with less than 0.5% carbon. Annealing and normalizing can also refine the grain and uniform the structure, which is ready for the later heat treatment. Annealing and normalizing are usually arranged after blank manufacturing and before rough machining.

Aging treatment is mainly used to eliminate the internal stress in blank manufacturing and machining. In order to avoid excessive transportation workload, for parts with general accuracy, it is enough to arrange a time-dependent treatment before finishing. However, for parts with high accuracy requirements, two or more aging processes should be arranged. Simple parts generally can not be aged. In addition to castings, for some precision parts with poor rigidity, in order to eliminate the internal stress produced in processing and stabilize the machining accuracy of parts, multiple aging treatment is often arranged between rough machining and semi finish machining. Some shaft parts processing, after straightening process also need to arrange aging treatment.

Quenching and tempering is to carry out high temperature tempering after quenching, which can obtain uniform and fine tempered sorbite structure and prepare for reducing deformation during surface quenching and nitriding treatment. Therefore, quenching and tempering can also be used as preparatory heat treatment.

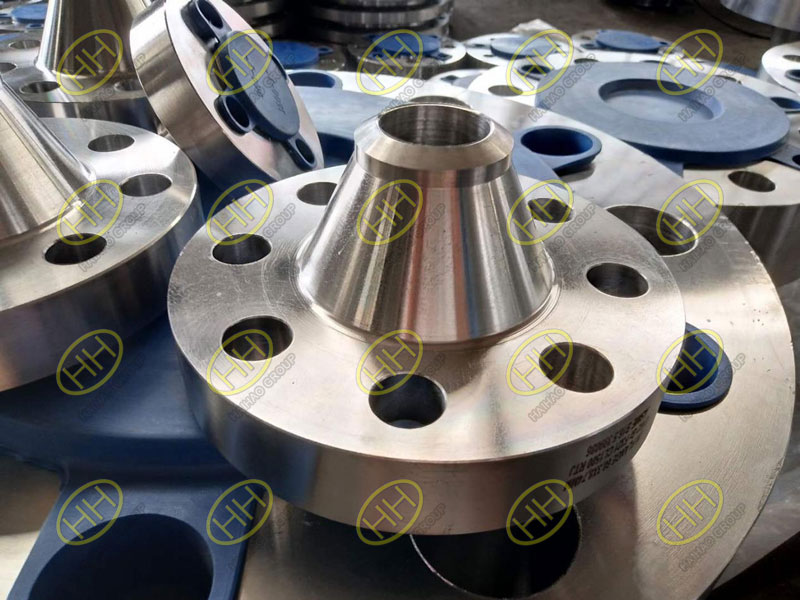

On the flange production, Haihao Group strictly controls the quality of flange heat treatment to meet the needs of customers. We have more than 30 years of experience, familiar with the flange preheating method, welcome new and old customers to consult.Email:sales@haihaogroup.com