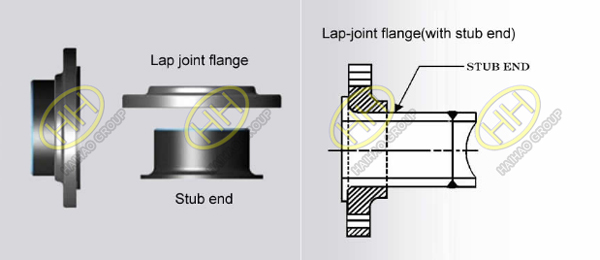

Methods for assembling stub ends and lap joint flanges

Stub ends and lap joint flanges can be assembled following this process:

- The lap flange is slipped over and onto the stub end flange.

- The stub end flange is then welded onto a pipe spool, using an approved Welding. Procedure specification (WPS), by a qualified welder. The lap joint flange, backing flange, can revolve around the stub end, which is now attached to the piping spool.

- The bolt holes of the lap joint flange can now be orientated and aligned with the bolt holes of a mating flange of the same ASME designate rating and NPS.

The lap joint flange can be mated to any flange covered in ASME B16.5, weld neck, slip on, threaded, socket weld, another lap joint flange. It can also be mated to a fabricated plate flange with compatible, bolting dimensions.