Large wind power flange forgings

The wind power flange is the main connecting part of the wind turbine tower. Because the tower height can reach more than 100 meters, the flange has to bear a variety of loads in the air, and the stress situation is very complex. In case of severe weather such as extreme low temperature, typhoon and sandstorm, its safe operation will face a serious test. Therefore, there are high requirements for the mechanical properties, internal organization state, process performance and low-temperature toughness of the wind power flange in production.

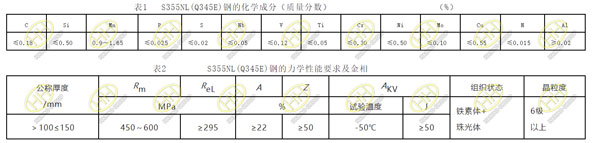

The material of the wind power flange is weldable fine-grained structural steel S355NL or low-alloy high-strength steel Q345E. Because this steel has low carbon content, Mn is the main strengthening element, and some refined grain elements are added, with CEV less than or equal to 0.43. The welding performance is excellent. After forging, excellent comprehensive mechanical properties can be obtained through appropriate heat treatment.

The manufacturing process flow of Haihao wind power flange is: raw material re-inspection, blanking, heating, forging and opening, heating, ring rolling, heat treatment, rough machining, flaw detection, finishing, drilling and final inspection. The forging temperature is between 1230 ℃ and 800 ℃, and the forging ratio is generally controlled between 6-10.

Driven by the national energy conservation and emission reduction policies, new energy power generation projects have been more and more widely used in China. In recent years, Haihao has also been more and more involved in relevant projects. Last year, Haihao provided large-diameter flanges for many domestic wind power projects and participated in the supply and construction of domestic nuclear power plant pipelines. Haihao has specialized in producing pipe fittings such as flanges, steel pipes, elbows and tees for more than 40 years, and has rich product and project experience. We are committed to providing customers with one-stop service and one-time solution of various pipeline supporting products required by the project. Welcome to consult related products and services.