Introduction to weld overlay alloy material and the advantages of applying it to spectacle blind flanges

Weld overlay is a crucial process used to enhance the surface properties of base materials by welding a layer of high-performance alloy, such as inconel 625, onto the substrate. This method is widely used in industries that operate under harsh conditions, such as oil and gas, petrochemicals, and power generation. The inconel 625 alloy, a nickel-based superalloy, is renowned for its excellent mechanical properties and resistance to corrosion, oxidation, and extreme temperatures. When applied as a weld overlay to spectacle blind flanges, it provides significant advantages in terms of durability and longevity.

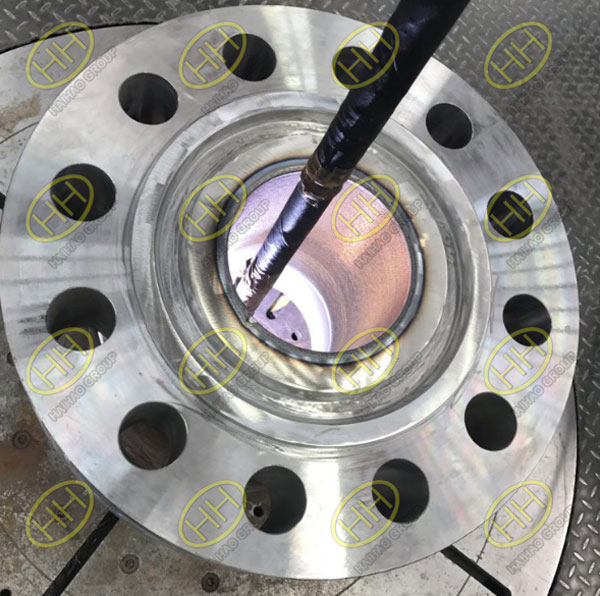

Flange with inconel 625 cladding

Properties of inconel 625 Weld Overlay

1.Corrosion Resistance:

One of the standout characteristics of inconel 625 is its superior resistance to a wide range of corrosive environments. This includes resistance to pitting, crevice corrosion, and stress-corrosion cracking, even in chloride-rich and acidic environments. This makes it ideal for applications where the spectacle blind flange will be exposed to aggressive chemicals or seawater.

2.High-Temperature Strength:

Inconel 625 retains its mechanical strength at temperatures ranging from cryogenic levels to over 980°C (1800°F). This high-temperature performance makes it a preferred material in applications involving extreme heat, where other materials might deform or lose their strength.

3.Oxidation and Scaling Resistance:

In addition to corrosion resistance, Inconel 625 is highly resistant to oxidation, which is vital in environments that involve high temperatures and oxygen exposure. The alloy forms a protective oxide layer on its surface, which shields it from further damage, preserving the integrity of the Spectacle Blind.

4.Excellent Weldability:

Inconel 625 has good weldability without the need for post-weld heat treatment. This is advantageous during the weld overlay process as it simplifies production while maintaining the alloy’s mechanical and corrosion-resistant properties.

Flange with inconel 625 cladding

Advantages of spectacle blind flanges with inconel 625 weld overlay

By applying an inconel 625 weld overlay to spectacle blind flanges, several advantages are realized, particularly in demanding industrial applications:

1.Extended Service Life:

The inconel 625 layer dramatically extends the lifespan of the spectacle blind flange by providing superior protection against corrosion, erosion, and mechanical wear. This is particularly beneficial in environments such as offshore platforms, chemical plants, and refineries, where components are constantly exposed to corrosive substances.

Cost Efficiency:

While a spectacle blind flange made entirely of inconel 625 would be costly, the weld overlay process allows for the use of a more economical base material like ASTM A516 Gr.70 carbon steel. The overlay provides the performance benefits of inconel 625 without the expense of a fully alloyed product, offering an optimal balance between performance and cost.

High Strength and Toughness:

The base material, ASTM A516 Gr.70, provides excellent toughness and strength, while the inconel 625 overlay enhances the corrosion and oxidation resistance. This combination ensures that the spectacle blind flange is durable and can withstand both mechanical stress and harsh environmental conditions.

Versatility in Extreme Conditions:

The dual properties of the base material and the weld overlay make these spectacle blind flanges suitable for a wide range of operating conditions, from high temperatures to highly corrosive environments. This versatility reduces the need for frequent replacements, improving the efficiency of industrial processes.

Reliable Sealing Function:

As spectacle blind flanges are used to isolate sections of piping systems, ensuring a tight seal is critical. The weld overlay of inconel 625 enhances the sealing capability by resisting degradation that could affect the performance over time.

The combination of inconel 625 weld overlay with a spectacle blind flange provides a robust solution for applications that demand high resistance to corrosion, extreme temperatures, and mechanical wear. This advanced manufacturing technique allows for the economic use of materials while delivering the durability and reliability needed for critical pipeline systems. As a result, companies in industries such as oil and gas, chemical processing, and power generation can rely on spectacle blind flanges with inconel 625 weld overlay for their most demanding operational environments, ensuring long-term performance and reduced maintenance costs.