Introduction of tongue and groove face flange

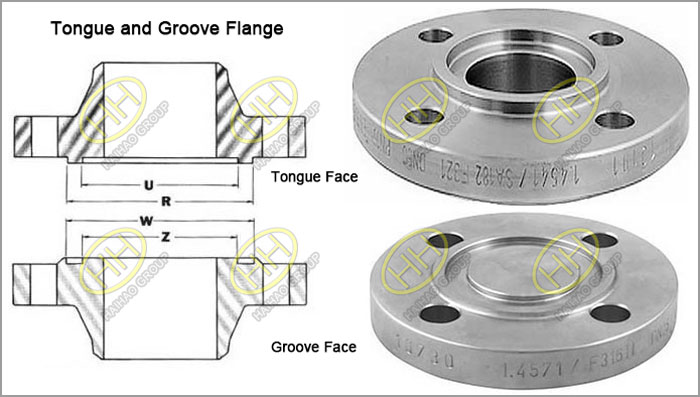

The sealing surface of the tongue and groove face flange is composed of a tongue face and a groove face,and the gasket is placed in the groove.Tongue and Groove faces of this flanges must be matched.One Tongue flange face has a raised ring machined onto the flange face while the mating grooving flange has a matching depression machined into it’s face.Tongue-and-groove facings are standardized in both large tongue and groove flange and small tongue and groove flange,different from male-and-female in that the inside diameters of the groove and tongue do not extend into the flange base,thus retaining the gasket on its inner and outer diameter.

Specification for tongue and groove flange:

Dimensions: ANSI B16.5,ANSI B16.47 Series A & B,MSS SP44,ASA,API-605,AWWA,Custom Drawings

Size: 1/2″ (15 NB) to 48″ (1200NB)

Class: 150 LBS,300 LBS,600 LBS,900 LBS,1500 LBS,2500 LBS,DIN Standard ND-6,10,16,25,40 Etc.

DIN: DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS: BS4504 , BS4504, BS1560, BS10

Flange Face Type: Flat Face(FF),Raised Face(RF),Tongue & Groove (RF),Ring Type Joint (RTJ)

Material of Tongue and Groove Flanges :

Carbon Steel Tongue and Groove Flanges:

ASTM A 105 / A 266 Gr. 2 (high temperature carbon steel)

ASTM A350 LF1 to LF3 (low temperature carbon steel)

ASTM A694 Gr. F42 / F52 / F56 / F60 / F65 (high yield carbon steel flange to match API 5L linepipes)

Alloy Steel Tongue and Groove Flanges:

ASTM A182 Gr. F1 / F2 / F5 / F9 / F11 Cl. 2 / F12 Cl. 2 / F22 Cl. 3 / F91 (alloy steel flanges)

Stainless / Duplex Steel Tongue and Groove Flanges:

ASTM A182 F 304/304L, 316/316L, 321, 347, 348 (stainless steel flanges), 904/904L

ASTM A182 F51 (duplex flanges) / F53-F55 (superduplex)

Nickel Alloys / Superalloys Tongue and Groove Flanges:

ASTM B166 UNS NO6600 (inconel 600)

ASTM B564 UNS N06625 (Inconel 625)

ASTM B425 UNS-NO8800 (Incoloy 800)

ASTM B564 UNS N08825 (Incoloy 825)

ASTM B160 UNS N0200 (Nickel 200)

ASTM B564 UNS N04400 (Monel 400)

ASTM B564 UNS N10276 (Hastelloy C-276)

Advantages of tongue and groove face flange:

(1) the gasket of this flange in the groove will not be extruded,compression area is the smallest, the gasket force uniform;

(2) since the gasket is not in direct contact with the medium,it is least affected by the corrosion of the medium and the penetration of the pressure mechanism;

(3) due to the narrow sealing surface,the required bolt force is small,suitable for higher pressure, the occasion of strict sealing requirements, such as high pressure,flammable,explosive,toxic media and other occasions.

Disadvantages of tongue and groove face flange:

the structure of this flange is complex,and its gasket is squeezed in the groove is not easy to clear,replacement gasket is difficult.In addition,this kind of flange should be protected in transportation to avoid collision deformation.

Application of tongue and groove flange:

Tongue and Groove Flanges Application:

- Stainless Steel Tongue and Groove Flange uses in Oil and Gas Pipeline

- A182 SS Tongue and Groove Flange uses in Chemical Industry

- Stainless Steel 304 Tongue and Groove Flange uses in Plumbing

- 316 Stainless Steel Tongue and Groove Flange uses in Oil & Gas Industry

- Stainless Steel 304L Tongue and Groove Flange uses in Water Supply Systems

- 316L SS Tongue and Groove Flange uses in Paper & Pulp Industry

- ASTM A105 Tongue and Groove Flange uses in Power Plant

- A234 Alloy Steel Tongue and Groove Flange uses in Fabrication Industry

- Carbon Steel A350 LF2 Tongue and Groove Flange uses in General purpose applications

- LTCS Tongue and Groove Flange uses in Structural Pipe

- ST 37-2 Tongue and Groove Flange uses in Heat Exchangers

Hebei Haihao Group can produce various types of tongue and groove face flanges according to clients’ needs.We also can supply flat face,raised face flanges,if you want to know more about our flanges products,please email us:sales@haihaogroup.com