How to choose between the spring washers and flat washers?

Flat washers and spring washers are well-known and frequently used washers. Due to the different characteristics of the two,in actual application,the two must be distinguished, otherwise not only cannot play the role of the gasket,but may cause some unnecessary trouble.

As the professional flange manufacturer, we have always involved the matching use of gaskets. Here are the advantages and disadvantages of both.

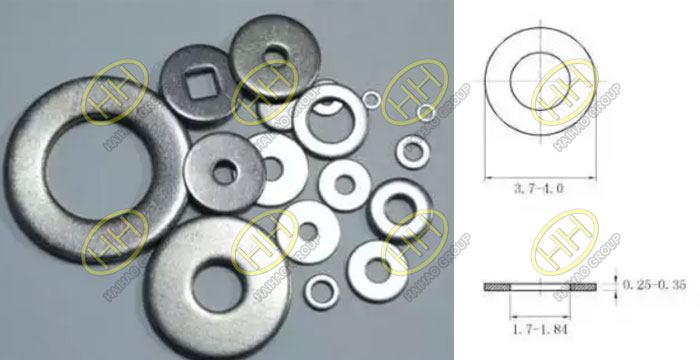

Flat washers

Flat washers are generally used to increase the contact area between parts. Its advantages and disadvantages are described below:

Advantage:

① By increasing the contact area, components can be protected from damage;

② By increasing the contact area, reducing the pressure between the nut and the device, thereby protecting it.

Disadvantages:

① The flat washer cannot play the role of anti-vibration;

②The flat washer has no effect of preventing loosening.

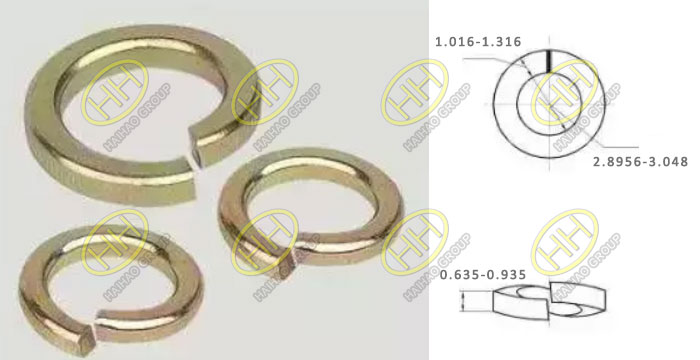

Spring washer

The spring washer can rely on its own elastic force to play a role in preventing loosening. Its advantages and disadvantages are as follows:

Advantage:

① The spring washer has a good anti-loose effect;

② Spring washer has better anti-vibration effect;

③ Low manufacturing cost;

④ Easy to install.

Disadvantages:

Spring washers are greatly affected by materials and processes. If the material is not good, the heat treatment is not well controlled, or other processes are not in place, it is easy to crack.

In actual use, due to the different emphasis of flat washers and spring washers, in many occasions, the two are matched and used together. This has the advantages of protecting parts, preventing nuts from loosening, and reducing vibration, which is great choice.