Haihao Group’s dedication to high-quality forged flanges for wind power towers

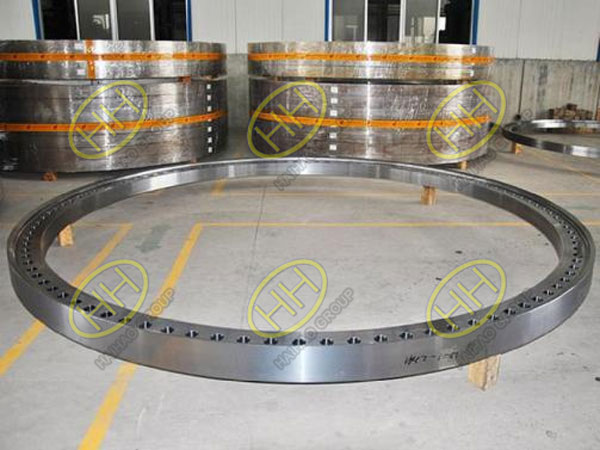

In the world of wind power, the demand for large wind turbine tower flanges is steadily increasing. At Haihao Group, we understand the importance of delivering top-quality products to meet the rigorous requirements of the industry. Here’s how we achieve excellence in crafting these essential components:

1.Superior Steel Material:

Large wind turbine tower flanges are typically forged from S355NL steel (EN10025-3), a low-alloy high-strength structural steel known for its low carbon content. Manganese is the primary strengthening element, and a small amount of grain-refining elements is added. To ensure the low-temperature toughness of flange forgings, we rigorously control the phosphorus and sulfur content during steel smelting, effectively reducing the inclusion content. We also strictly limit the presence of the “five harmful” elements: lead (Pb), tin (Sn), arsenic (As), antimony (Sb), and bismuth (Bi). These low-melting-point elements, if present in the steel, result in a significant reduction in plasticity and toughness when the steel melts during heating.

2.Precision Forging Process:

To meet the high technical requirements for large wind turbine flanges, we not only control the chemical composition of the steel ingots and the content of residual harmful elements but also plan a strict forging process. This ensures that the forgings achieve a sufficient forging ratio, breaking down dendritic structures within the steel, fully compacting the internal metal, reducing internal defects, and enhancing the internal metal’s density.

3.Controlled Heat Treatment:

The heat treatment process is critical to ensuring the quality of flange forgings. We heat the forgings to 650°C and maintain them at this temperature for 1.5 to 2 hours to eliminate thermal stress. Beyond 650°C, rapid heating takes place, quickly passing through phase transition temperatures, increasing the degree of overheat during the phase transition of steel, and improving the nucleation rate of austenite to refine austenite grain size. After reaching 910°C, we perform rapid cooling through forced air blowing and spraying in the quenching tower to accelerate the cooling rate. To ensure even cooling, the forgings are continuously rotated until the cooling process is complete. The result is a fine and uniform pearlite + ferrite structure with minimal differences in grain size between longitudinal and transverse sections. Mechanical properties, including tensile strength, yield strength, elongation, and impact energy absorption, consistently exceed the technical requirements.

Haihao Group takes immense pride in our ability to produce high-quality wind turbine tower flanges. Our dedication to using top-notch materials, rigorous forging processes, and precise heat treatment procedures allows us to deliver products that meet and exceed customer expectations. We ensure the superior strength and ductility of our flanges and guarantee that they meet all technical requirements, all while minimizing anisotropy differences. When it comes to large wind turbine flanges, Haihao Group is the name you can trust for excellence.

For more information about our range of products and services, feel free to contact us. We are your trusted partner in the wind power industry.