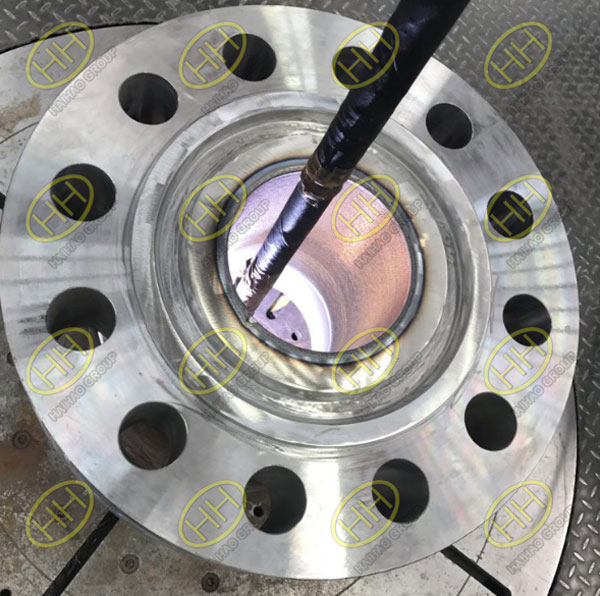

Flange with inconel 625 cladding

A weld overlay cladding flange is also known as cladding flange,it is a flange used of a weld overlay cladding technology process to build up the corrosion resistant alloy(CRA) layer to substitute the solid metal Flanges. The surfacing process of surfacing flange (weld overlay cladding ) is a metallurgical composite process of two different metals.

In offshore projects or subsea piping, the corrosion resistance requirement is exceptionally undebatable . Cladding is better way to prevent corrosion of the low alloy material involved in the flange forging. Cladding over carbon steel pipes is cheaper than using duplex stainless steel or Ni base alloy.

Nickel Alloy 625 is used both for its high strength and outstanding aqueous corrosion resistance base material or or as an welding filler. The strength of Nickel Alloy 625 is primarily a solid solution effect from molybdenum and columbium. Nickel Alloy 625 has excellent weldability. The matching filler metals are often used for dissimilar metal joining and to weld the aqueous corrosion steel . Welding INCONEL alloy 625 is readily joined by conventional welding processes and procedures.

Normally our Weld Overlay and Process Used is like below

The clad welding i was conducted using GMAW process and after a number of tests i.e. cladded flange was qualify for the subsea application and approved as per requirement. The flanges had grooves which were prone to wear and corrosion and hence were required to be welded with corrosion resistance material (625). The welding was carried out by automated GMAW process in the grooved, cladded region was machined to the required dimension, inspected &tested.