Factors influencing tube sheet corrosion

Tube sheets are mainly used in chemical containers, such as shell-and-tube heat exchangers, pressure vessels, boilers, condensers, central air conditioning units, evaporators, and seawater desalination systems, playing a role in supporting and securing the tubes. Since tube sheets come into contact with various chemical media, they are prone to corrosion. Additionally, a certain amount of galvanic corrosion can occur between the tube sheet and the heat exchanger tubes. There are multiple factors influencing tube sheet corrosion; this article summarizes the following five:

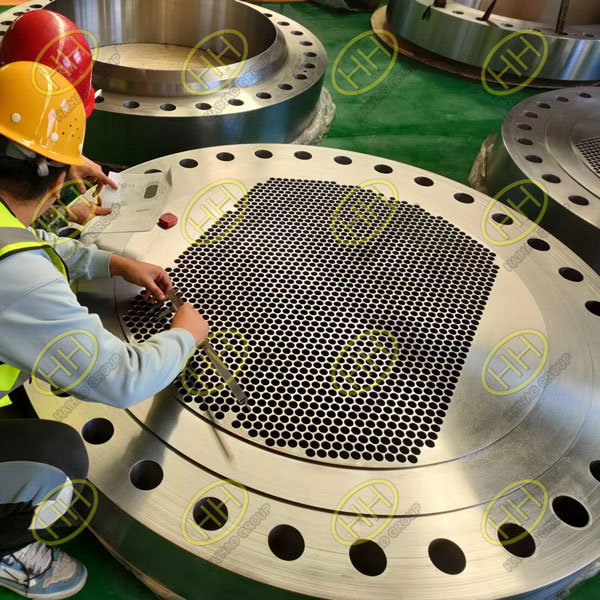

tube sheet inspection

1.Composition and Concentration of the Medium: The effect of concentration varies. For example, in hydrochloric acid, generally, the higher the concentration, the more severe the corrosion. In sulfuric acid, carbon steel and stainless steel experience the most severe corrosion at a concentration of around 50%, but when the concentration exceeds 60%, the corrosion rate sharply decreases.

2.Impurities: Harmful impurities include chloride ions, sulfide ions, cyanide ions, and ammonia ions, which can cause severe corrosion under certain conditions.

3.Temperature: Corrosion is a chemical reaction, and for every 10°C increase in temperature, the corrosion rate typically increases by about 1-3 times. However, there are exceptions.

4.PH Value: Generally, the lower the pH value, the greater the metal corrosion.

5.Flow Rate: In most cases, the higher the flow rate, the more severe the corrosion.

Understanding the factors affecting tube sheet corrosion is crucial for its anti-corrosion protection. As an expert in the pipeline systems field, Haihao Group possesses comprehensive knowledge of various pipeline systems. If you wish to learn more about our products, please feel free to contact us.Email:sales@haihaogroup.com