Enhance your pipeline with ASME B16.5 RF SA-182 F316/316L flange from Haihao Group

Haihao Group proudly announces a recent partnership with a client from the United Kingdom, who has placed an order for a batch of ASME B16.5 RF SA-182 F316/316L weld neck flange, featuring two different sizes: 2″ and 20″. Additionally, the order includes ASME B16.5 18″ SO Flange RF SA-182 F316/316L.

Distinguishing itself as a leader in the industry, Haihao Group delivers premium quality products tailored to meet the diverse needs of its clientele. Let’s delve into the key features of these flanges and explore the differences between SO (Slip-On) flanges and WN (Weld Neck) flanges, shedding light on the importance of flange sealing surfaces.

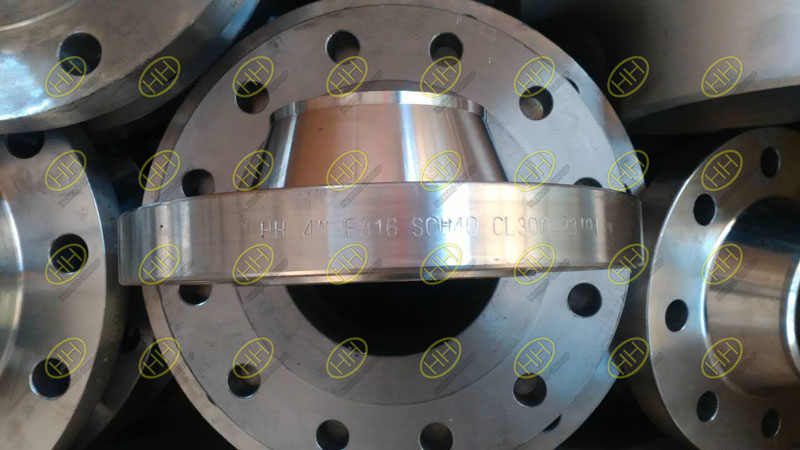

ANSI ASME B16.5 class 300 A182 F316 weld neck flange

ASME B16.5 RF SA-182 F316/316L Flange:A Benchmark in Quality

The ASME B16.5 RF SA-182 F316/316L flange exemplifies excellence in design and functionality. Crafted with precision using high-grade materials, these flanges ensure optimal performance and durability in diverse industrial applications.

Distinguishing SO Flanges from WN Flanges

EN 1092-1 forged slip on flanges

Slip-On (SO) Flanges:

Ease of Installation: SO flanges slide over the end of pipes, facilitating quick and hassle-free installation.

Cost-Effective Solution: Known for their simplicity, SO flanges offer a cost-effective option for connecting pipes.

Limited Pressure Rating: While suitable for low-pressure applications, SO flanges may not be ideal for high-pressure environments.

Weld Neck (WN) Flanges:

Enhanced Strength and Stability: WN flanges feature a protruding neck that provides added reinforcement, enhancing the structural integrity of the joint.

Superior Performance in High-Pressure Environments: With their welded connection, WN flanges offer greater resistance to pressure and temperature fluctuations, making them ideal for demanding applications.

Precise Alignment: The welded neck ensures accurate alignment of the flange and pipe, minimizing the risk of misalignment and leakage.

Understanding Flange Sealing Surfaces

Flange sealing surfaces play a critical role in ensuring leak-free connections in piping systems. Common sealing surface types include:

Flat Face (FF):Suitable for low-pressure applications, FF flanges feature a flat mating surface.

Raised Face (RF):RF flanges feature a raised ring around the bore, allowing for better alignment and improved sealing performance.

Ring Joint (RTJ):RTJ flanges use a metal ring gasket to achieve a tight seal, making them suitable for high-pressure and high-temperature applications.

With Haihao Group’s ASME B16.5 RF SA-182 F316/316L flange,customers can expect unmatched quality, reliability, and performance. Whether you require slip-on or weld neck flanges, we have the expertise and resources to meet your specific requirements.Contact us today to elevate your pipeline with superior flange solutions.