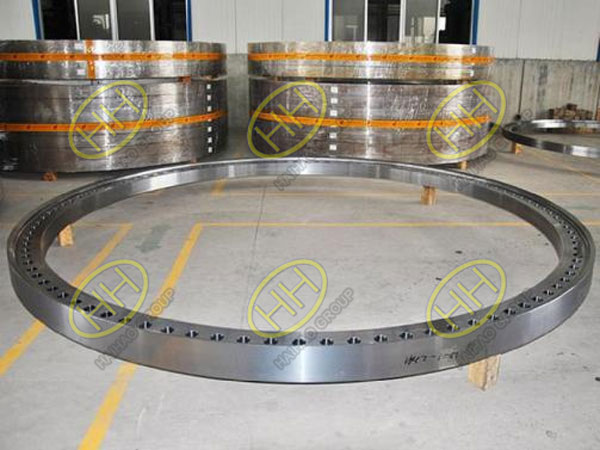

Arrange quality inspection for wind power flange

On January 20, Haihao signed a supply contract for wind power flange with the customer. After many technical consultations, the flange officially started production on January 23. According to the needs of customers, Q345E was used as the raw material for this production, and the content of non-metallic inclusions in the material was checked according to the requirements of ASTM E45 test method.

Now the main part of the flange has been produced. Today, the customer invited a third-party organization to Haihao to inspect the product. This quality inspection includes: 100% nondestructive testing and surface crack testing, ultrasonic testing, grain size testing, and appearance and size testing, and metallographic tests have been carried out on the longitudinal, radial, and circumferential directions of the flange, and 400-fold microscope photos have been taken. After quality inspection, Haihao’s products fully meet the needs of customers. After coating treatment, delivery will be arranged.

Haihao Group has a complete quality inspection system. From the arrival of raw materials to the delivery of finished products, Haihao has strict quality inspection requirements. In addition, Haihao products are subject to testing from a third party and can issue relevant testing reports. We have specialized in the production of flange, steel pipe, elbow, tee and other pipeline supporting products for more than 40 years, and the product quality has been unanimously recognized by the domestic and foreign markets. If you need related products, please feel free to contact us.