Haihao Group secures order for ASME B16.5 weld neck flanges from UAE client

Haihao Group is pleased to announce a significant order from a valued client in the UAE. The order comprises high-quality ASME B16.5 weld neck flanges (WN Flange) manufactured from ASTM A105N carbon steel with an alloy 625 overlay. This product is tailored to meet the stringent specifications and requirements of the oil and gas industry.

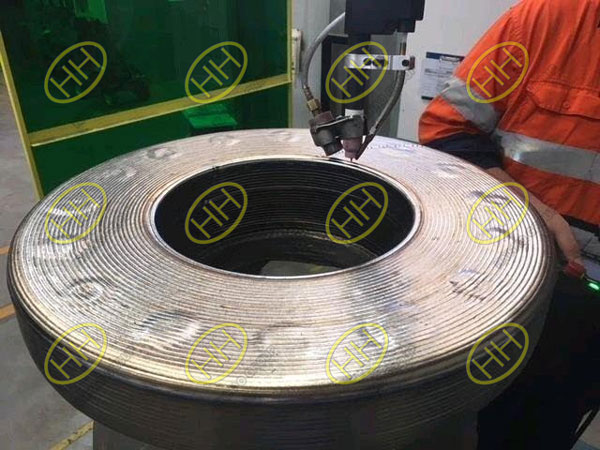

ASME B16.5 weld neck flange with alloy 625 overlay

Detailed Order Specifications

Product: 6″ Weld Neck Flange

Base Material: Carbon Steel per ASTM A105N

Overlay Material: Alloy 625

Overlay Specifications: Minimum of two layers, achieving a thickness of at least 3mm

Flange Class: Class 1500

Flange Type: Ring Joint (RTJ)

Schedule: XS (10.97mm thickness)

Standards Compliance: ASME B16.5

NACE Compliance: Material meets the requirements of NACE MR0175

Delivery Time: 25 days

Technical Highlights

The 6″ Weld Neck Flange features an overlay of Alloy 625 on the RTJ face. Alloy 625 is renowned for its excellent corrosion resistance and strength at high temperatures, making it ideal for demanding environments such as those encountered in the oil and gas sector. The overlay process involves applying a minimum of two layers of Alloy 625, ensuring a robust and durable coating with a thickness of at least 3mm.

The carbon steel base material, ASTM A105N, provides the necessary mechanical strength and toughness, while the Alloy 625 overlay enhances the flange’s resistance to corrosion and wear. This combination ensures the flanges can withstand harsh operating conditions and extend the service life of the equipment.

ASME B16.5 weld neck flange with alloy 625 overlay

Commitment to Quality and Timely Delivery

Haihao Group is committed to delivering high-quality products that meet stringent industry standards. The flanges are manufactured in compliance with ASME B16.5 and meet the specific requirements of NACE MR0175, ensuring their suitability for sour gas applications and other corrosive environments.

Our team is dedicated to meeting the 25-day delivery timeline, demonstrating our capability to fulfill urgent orders without compromising on quality. We utilize state-of-the-art manufacturing processes and rigorous quality control measures to ensure each product meets the specified requirements and exceeds customer expectations.

This order highlights Haihao Group’s expertise in providing specialized flanges for critical applications. Our ability to deliver high-quality products within tight deadlines underscores our commitment to customer satisfaction and industry excellence. We look forward to continuing to support our clients with reliable, high-performance piping components tailored to their specific needs.

For more information or to place an order, please contact Haihao Group’s sales team. Stay updated with our latest projects and product offerings by visiting our website or following us on social media.