Material and inspection of tube sheet flange

According to the different use environment, different materials are used. Generally, Q345R container plates are used, such as primary and secondary pressure vessels, and carbon steel composite plates can be used without corrosive medium circulation. When encountering strong acid, high pressure and high temperature, nuclear energy and other environments, stainless steel, 16 manganese, titanium alloy and other corrosion-resistant materials are required. The application of new synthetic materials brings new opportunities for flange tube plate flange products.

The machining accuracy of the tube sheet flange, especially the tube hole spacing and tube diameter tolerance, verticality, and smoothness greatly affect the assembly and service performance of chemical equipment. Therefore, the detection of the tube sheet flange is also a part of our great concern.

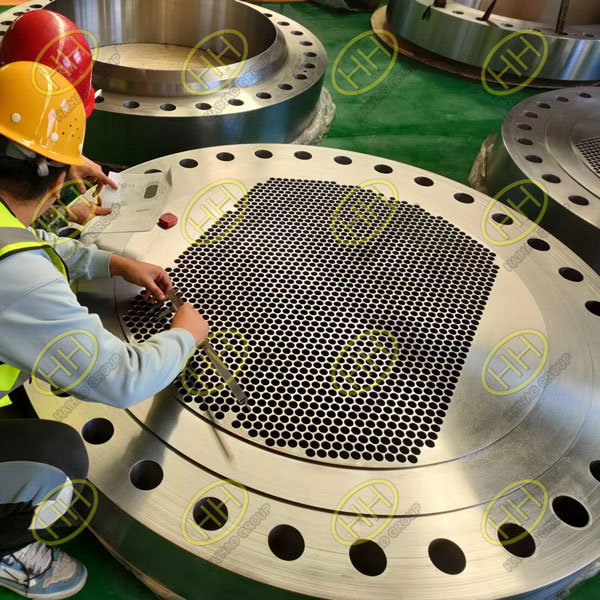

In the inspection process of the tube sheet flange, the main inspection indicators are hole position, hole diameter tolerance, hole smoothness, presence or absence of burrs, slotting position, etc., as shown in the figure. For the double-flange tubesheet flange, more attention is paid to the hole position during the inspection process, and the hole position matching degree of the two flange tubesheet flanges is very important. Compared with thicker tube-sheet flanges (above 300mm), the verticality of the holes is very important, and more sophisticated equipment is required for detection.

As shown in the picture, the professional inspectors of Hebei Haihao Group are inspecting the tube-sheet flange that has completed the production task, and passed the inspection according to the customer’s requirements, including flange appearance inspection, dimensional inspection, material inspection, NDT, etc. Welcome customers with this demand to inquire and purchase!