Do you really know about the orifice flange?

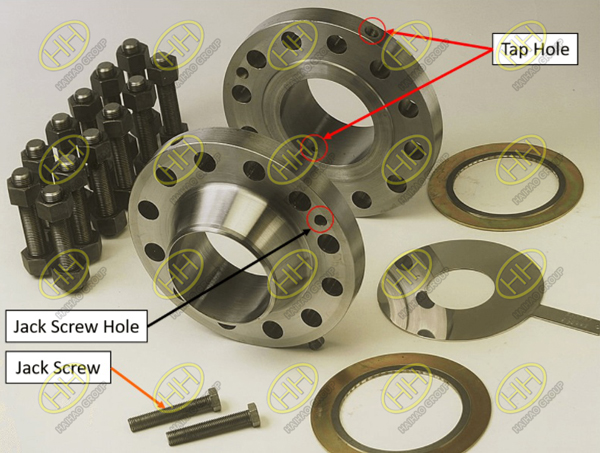

Orifice flanges are used with orifice flow meter that is why it called orifice flanges. The purpose of orifice meter is to measure the flow rate of either liquids or gasses that pass through the pipe. These flanges are always used in a set of two. In this image,you can see the complete set of items that used with orifice flange.

Two flanges, orifice plate, gaskets, pressure taps and Jack screw hole with two jack screws. I will explain each of these.

Orifice flanges are available from Class #300 to Class #2500. Class #300 flanges are available in threaded, slip-on and weld neck end types. Whereas, Class# 600 and above flanges are available in only weld neck type end connection. Dimensions of these flanges are covered in ASME B16.36.

Orifice plate is a specially designed plate with a hole at center that creates a pressure drop to measure the flow rate. Please note that orifice plate is not interchangeable. It means you cannot use orifice plate of water line into the hydrocarbon line. Size of the hole and the angle, as shown in the image, are specifically designed for the service.

Next is the gasket. There are only two types of flange faces are available in orifice flange. Raised face and RTJ face. Therefore, only spiral wound and RTJ gaskets are used that too in the set of two for each side of the orifice.

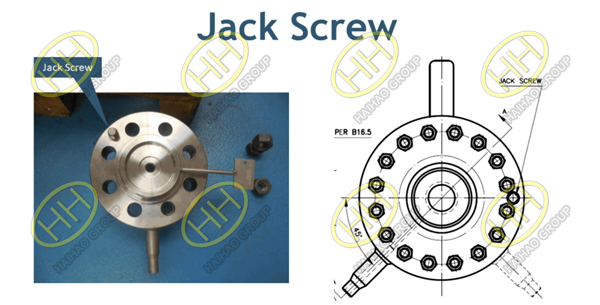

These jack screws are drilled on the flange circle centreline at 90 degrees to the tapped hole and used to facilitate separating the flanges for inspection or replacement of the Orifice Plate and gaskets.

Pairs of pressure “Tappings”,as highlighted in the image, are machined into the orifice flange.Note that these holes are directly opposite each other.

Tap holes are either tapped ½” NPT or ½” NPS socket connection. A one tap hole from each flange is used to connect instruments with the help of tube that allows liquid or gas to reach the instrument. You can see this in the image. The other one hole is sealed with a plug.

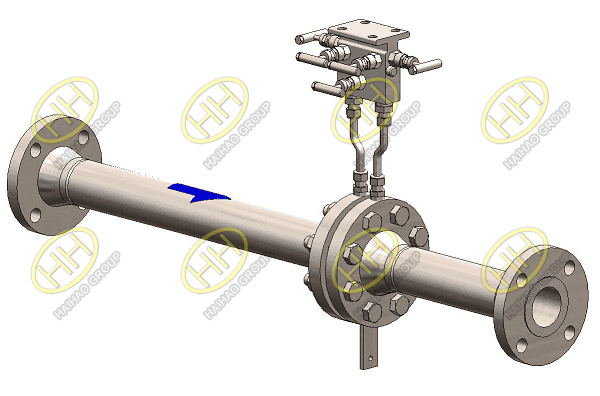

Orifice Flange Installation

Orifice flanges are installed in a straight run of pipe in order to avoid turbulence at the plate. As a rule of thumb, an orifice flange has ten diameters of straight pipe upstream and five diameters of straight pipe downstream. In general pressure taps kept at the same elevation to each other.

Orifice flanges are available in Class# 300, 600, 900, 1500 and 2500-pound rating and the Dimensions are covered in ASME B16.36. Images show the installation setup of orifice flow meter.

As a professional flange supplier,commonly we supply the weld neck and slip on orifice flange in standard ANSI B16.36,and other types flange is also available to design,when the sizes are more than 24″,we should use the MSS SP-44 as the standard.If you want to know more about our products,please feel free to contact us.Email:sales@haihaogroup.com