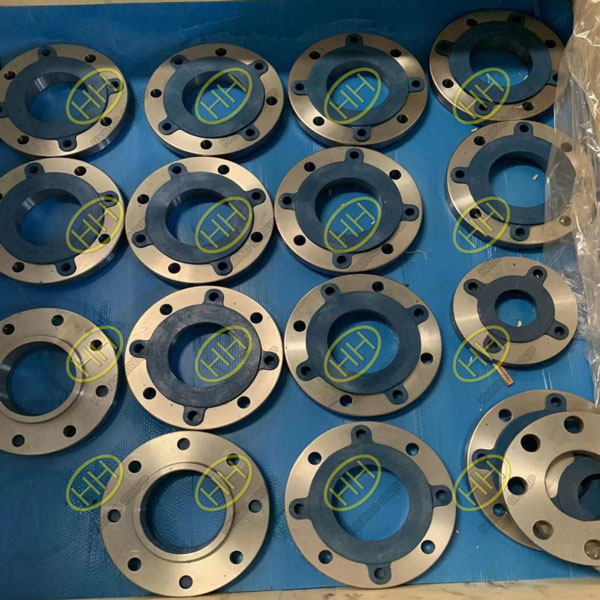

JIS B2220 30K SS400 Rolled Forged Ring Plain Flange

JIS B2220 30K SS400 Rolled Forged Ring Plain Flange

Followings are the definition, information and application of various types of flanges:

The rolled-forging ring flange produced by Hebei Haihao Group means the large size ring flanges produced by rolled forging, not the open die forging process.From the shape,it is a customized flange of plain type, weld neck shop or other types,and always have a large diameters.

Sealing face: Raised Face(RF), Flat Face(FF), Ring Type Joint(RTJ).

Flange face finishing, MSS-SP-6, such as: Stock finishing, Spiral serrated finishing, concentric serrated finishing, smooth finishing etc.

Coating: Black paint, Yellow paint, Vanish oil etc.

Certificate: BS EN10204 3.1 MTC, ABS, PED 97-23-EC, CE, ISO, API approved.

Application: Water Treatment, Shipbuilding industry, sea Platform, Petrochemical & Gas industry, Power plant, Valve industry, Construction, Chemical industry, General piping system etc.

Packing: Wooden case, Plywood case, Pallet.

Marking: MSS-SP-25, necessary information of flange specification, Customized marking is available.

Process of Rolled Forging:

The rolled forged ring flanges are often produced by a process called ring rolling, the production begins with a circular metal that has been pierced by our pressing machine, then this pressed metal should be heated and bring to the rolling mills, there is a mandrel bar on the rolling mill, the mandrel bar will drive the metal roll under pressure to make the height and thickness smaller, and the diameters of ring larger. After finish the rolled forging, our CNC vertical lathe and drilling equipment will finish the machining work for the ring flanges.